什么是熱成型鋼板車身件?

將硼鋼鋼板(初始強(qiáng)度為500~600MPa)加熱至奧氏體化狀態(tài)

,快速轉(zhuǎn)移到模具中高速沖壓成形,在保證一定壓力的情況下,制件在模具本體中以大于27℃/s的冷卻速度進(jìn)行淬火處理,保壓淬火一段時間,以獲得具有均勻馬氏體組織的超高強(qiáng)鋼零件(1300-1600Mpa)。為何要使用熱成型鋼板車身件?

極高的材料強(qiáng)度及延展性。一般的高強(qiáng)度鋼板的抗拉強(qiáng)度在400-450MPa左右

,而熱成形鋼材加熱前抗拉強(qiáng)度就已達(dá)到500-800 MPa,加熱成形后則提高至1300-1600 MPa。因此由熱成型鋼板制成的車身極大的提高了車身的抭碰撞能力和整體安全性有效的減輕整車重量,節(jié)約能耗

。由于熱成型鋼板極高的材料強(qiáng)度,因此在設(shè)計(jì)時可以用一個熱成形零件代替多個普通鋼板的零件。這種零件具有厚度薄、重量輕、強(qiáng)度高,相比冷沖壓回彈性小,適合制造汽車A柱加強(qiáng)版、B柱加強(qiáng)版、地板部件、前端等,可為汽車提高安全性,減輕重量。

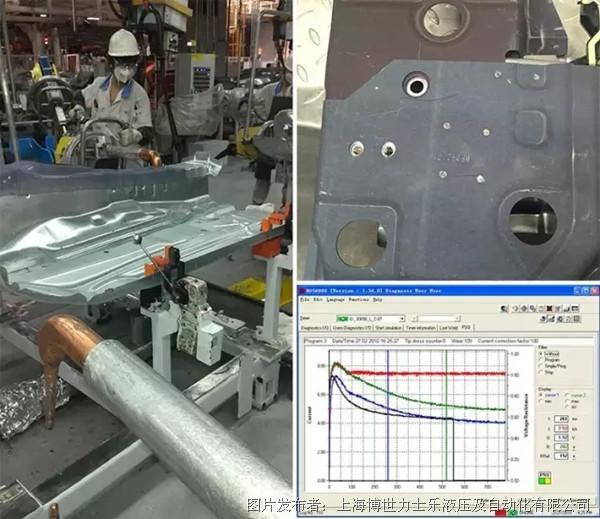

地板加強(qiáng)板使用了熱成型鋼板

側(cè)圍的A/B 立柱加強(qiáng)版使用了熱成型鋼板

正如上述

,熱成型鋼板有諸多優(yōu)勢,故在汽車廠得到了越來越普遍的應(yīng)用。但是,由于熱成型鋼板的電阻點(diǎn)焊的焊接性能非常特別,焊接參數(shù)帶非常窄,不同的廠家提供的熱成型鋼板的焊接電阻也差別大,進(jìn)口的和國產(chǎn)的熱成型鋼板的電阻焊接性能也相差較大,這些都給汽車廠的零件的點(diǎn)焊工藝提出了嚴(yán)重的挑戰(zhàn)。汽車廠很難解決熱成型鋼板點(diǎn)焊時出現(xiàn)的大飛濺和大毛刺,于是,只能采用后續(xù)的毛刺打磨工序,來解決這個問題。設(shè)定打磨工序,不但污染環(huán)境,浪費(fèi)人力物力,而且也整體降低了汽車零部件的生產(chǎn)效率。

熱成型鋼板點(diǎn)焊時

使用熱成型板中頻點(diǎn)焊技術(shù) — 實(shí)現(xiàn)無飛濺

榮仕杰的中頻電阻點(diǎn)焊,使用的是動態(tài)電阻樣本曲線的可視化方式

目前

英文版:

Rong Shijie hot forming plate spot welding technology. 本文標(biāo)簽:

熱成型板焊接

點(diǎn)焊機(jī)器人

咨詢熱線

Abstract: Rongshijie's IF adaptive resistance spot welding uses a visualization method of dynamic resistance sample curve, which can easily obtain the dynamic resistance characteristic curves

of various thermoformed steel sheets, and analyze in detail, different types and different manufacturers. The dynamic resistance characteristic curve of the thermoformed steel sheet is provided, so that the qualified welding specifications of various

thermoformed steel sheets and the dynamic resistance sample curve thereof can be quickly obtained; the qualified solder joints of the welded thermoformed steel sheet can be accurately obtained (no splash, no burr) Immediately, the dynamic resistance

sample curve is downloaded to Bosch's welding controller. Next, the adaptive adjustment function is turned on, so that the quality of the welded joint of the thermoformed steel plate can be perfectly closed-loop controlled without splashes and burrs.

Thoroughly solve the welding process problems that have long plagued automobile factories.

What is a thermoformed steel body part?

The boron steel plate (initial strength is 500~600MPa) is heated to the austenitizing state, and is quickly transferred to the high-speed stamping forming in the mold. Under the condition of ensuring a certain pressure, the workpiece is more

than 27 ° C / s in the mold body. The cooling rate is quenched and quenched for a period of time to obtain ultra-high strength steel parts (1300-1600 MPa) with uniform martensite structure.

Why use thermoformed steel body parts?

Extremely high material strength and ductility. The tensile strength of a general high-strength steel sheet is about 400-450 MPa, and the tensile strength of the hot-formed steel before heating is 500-800 MPa, and is increased to 1300-1600

MPa after heat forming. Therefore, the body made of thermoformed steel plate greatly improves the collision capability and overall safety of the vehicle body, and plays a good role in protecting the inside of the vehicle during the collision.

Effectively reduce the weight of the vehicle and save energy. Due to the extremely high material strength of thermoformed steel sheets, it is possible to replace a number of common steel sheet parts with a hot formed part during design. This

kind of parts has thin thickness, light weight and high strength. It is suitable for the manufacture of automobile A-pillar reinforced version, B-pillar reinforced version, floor parts and front end, etc., which can improve safety and reduce weight

for automobiles.

Floor reinforced panels use thermoformed steel sheets

Floor reinforced panels use thermoformed steel sheets

Side-walled A/B column reinforcement uses thermoformed steel

Side-walled A/B column reinforcement uses thermoformed steel

As mentioned above, thermoformed steel sheets have many advantages and are therefore becoming more and more popular in automotive plants. However, due to the special welding performance of the resistance spot welding of the thermoformed steel

sheet, the welding parameter band is very narrow, and the welding resistance of the thermoformed steel sheet provided by different manufacturers is also large, and the resistance welding properties of the imported and domestic thermoformed steel sheets

are also The large difference is a serious challenge to the spot welding process of the parts of the automaker. It is difficult for automakers to solve the large splashes and large burrs that occur during spot welding of hot-formed steel sheets. Therefore,

only the subsequent burr grinding process can be used to solve this problem. Setting the grinding process not only pollutes the environment, but also wastes manpower and material resources, and also reduces the overall production efficiency of auto

parts.

Severe post-weld burrs at each solder joint during spot welding of hot-formed steel sheets

Severe post-weld burrs at each solder joint during spot welding of hot-formed steel sheets

Use Rongshijie IF welding technology - spot welding of sputter-free, burr-free thermoformed steel sheets

Rong Shijie's medium frequency resistance spot welding uses a visualization method of dynamic resistance sample curve. It can easily obtain the dynamic resistance characteristic curves of various thermoformed steel sheets, and analyze in detail

the different types and different manufacturers provide thermoforming. The dynamic resistance characteristic curve of the steel plate, so as to quickly obtain the qualified welding specifications of various thermoformed steel sheets and their dynamic

resistance sample curves; after accurately obtaining the qualified solder joints of the welded thermoformed steel sheets (no splash, no burr), immediately The dynamic resistance sample curve is downloaded to Bosch's welding controller. Next, the adaptive

adjustment function is turned on, so that the solder joint quality of the thermoformed steel plate can be perfectly closed-loop controlled, and there is no splash and burr, and the long-term trouble is easily solved. The welding process of the car

factory.

At present, Rongshijie's sample curve thermoformed plate welded thermoformed steel plate technology has been widely used in most domestic automobile factories, and received rave reviews. Whether in the manual welding station or the robotic

welding station, Rongshijie's medium-frequency resistance spot welding technology can be perfectly interpreted.

Bosch Rexroth spot welding of thermoformed steel in manual work

淺談汽車螺母點(diǎn)焊機(jī)的焊接工藝

?" src="http://m.youke15.cn/resource/images/d93eb43cedec4cbc91164dc26d45c514_64.jpg" title="一套完整的焊接機(jī)器人工作站包括哪些設(shè)備

一套完整的焊接機(jī)器人工作站包括哪些設(shè)備?

庫卡ABB發(fā)那科點(diǎn)焊機(jī)器人機(jī)器人點(diǎn)焊焊接工藝介紹!

色偷偷男人的天堂aⅴ|

欧美曰本一本道无码dvd|

女超人满天星在线观看完整免费高清原声满

|

寡妇BWWBWWBWW|

中文字幕亚洲综合中文字幕|

国产AV一区二区二区蜜桃视频|

调教超级YIN荡护士H|

B站暴躁少女csgo|

我的朋友他的妻子|

国产精品理论片|

潘甜甜七夕43分23秒|

老公对不起在线看韩剧|

成片卡1卡啊2卡 3手机版|

freee sexmovies性|

妈妈总是坐在爸爸上面视频|

欧洲人妻丰满AV无码久久|

啪啪网站免费线看|

暴躁小姐姐csgo最新剧情|

情趣内衣姐|

99久久爱看免费观看|

咬女生小头头视频|

日本熟妇色XXXXXBBB日本少妇|

三更半夜在线观看视频|

caoprom最新超碰地址|

小s货张开腿让我c烂你的sb|

国产 在线 亚洲 欧美 动漫|

视频视频APP在线看|

英语老师乖乖挽起裙子怎么写作文|

小泽玛利亚的电影|

国内老熟妇对白HDXXXX|

好男人手机在线观看视频2019|

欧美亚洲另类在线高清|

伊人直播网站|

人口兽猪马狗免费观看动漫|

公之浮之手中字6|

97影院九七影院理论片在线|

成人理伦电片在线观看|

超在线观看视频播放|

亚洲人成无码网www|

午夜爱爱爱爱爽爽爽视频网站|

www.1688.gov.cn|

免费高清在线观看人数在哪|

黄金网站9.1入口免费|

最近中文字幕mv2018在线高清|

色拍拍拍免费视频在线|

久章草在线视频播放|

免费高清理伦片a片在线观看

|

csgo高清大片免费播放器|

色内射偷拍精品|

yellow高清在线观看免费观看视频

|

子夜精品视频在线|

欧美乱妇高清无乱码在线观看|

善良妈妈的朋友7在观有限中字

|

两个人日本的视频免费播放|

噜噜狠狠色综合久色A站网址|

少妇内射视频播放舔|

老公亲到我私下是不是真的爱你呢|

拔萝卜视频播放在线观看免费|

97资源总站(中文字幕)|

国产精品资源站在线观看

|

艾草仙姑在线视频免费影院|

国产 亚洲 中文字幕 久久网|

天天想你日日夜想你是什么歌|

扌喿辶畐小说内容|

成全视频在线观看免费高清版|

国色天香视频免费高清社区|

中文字幕亚洲综合久久|

婷婷色香五月综合网|

在线高清中文字幕电影久本草|

2012手机在线观看免费完整版|

熟妇人妻久久中文字幕|

草民2018韩国伦理片|

最好看的最新中文字幕1|

http://www.2222.gov.cn|

经典三级版在线播放|

苍井空图片|

国产婷婷一区二区三区|

两个人免费完整|

妖精视频高清|

不收费半夜年轻人看B站软件

|

电影金瓶梅|

老湿电影院免费10分钟|

freesexvide0s性21|

最近最新电影网免费观看|

蜜桃视频在线观看|

亚洲乱码爆乳精品成人毛片|

巜让上司满足的人妻|

妈妈的朋友5在完整有限木瓜|

浓精浇灌小白花最简单三个步骤|

小泽玛丽亚|

麻豆成人片在线无码|

沦为公交两奶头春药高潮迭起|

八戒影院看剧|

日本大片ppt免费ppt|

特别黄的视频免费播放|

免费观看已满十八岁动漫电视剧|

《炸裂吧!巨棒》免费观看全集|

欧美日日WWw|

freevide0fvixen性欧美|

www.xjxjxj18.gov.org|

丰满人妻一区二区三区视频53|

亚洲日韩视频高清在线观看|

97影院理论午夜伦不卡偷|

亚洲国产精品一在线观看蜜桃AV|

1v7视频|

好男人在线观看免费社区影院|

《教室里的激情》在线观看

|

鲁大师TV视频在线观看|

孩子玩着就C进我身体了|

邓超调侃从小看杨紫老师的戏长大|

三个人弄的我走不了路视频|

萝卜黄9.1|

欧美黑人又粗又大XXXX视频|

国产乡下三级|

桃子视频在线观看WWW|

8X8X海外华为永久免费2020|

番茄TODO在线视频播放|

purnhurb官网入口|

朋友妻别客气|

十分钟免费观看视频中国|

成年av动漫在线观看|

小蝌蚪视频|

揉?啊?嗯~出水了震动器韩漫|

范冰冰大尺度片段流出|

亚洲成成品网站源码中国有限公司|

亚洲 欧洲 综合 另类视频|

最新免费观看的电影|

女生吃小头头视频免费看|

4hc44四虎www|

暴躁老妈高清免费观看电视剧|

免费影视大全2019|

丰满的年轻搜子在线观看|

久久看片www.17c.com|

9久高清在线不卡免费无吗视频|

国产女人爽到高潮久久久

|

成人电影在线免费观看|

激情五月|

浴室高潮bd正在播放日本|

久草在线影院|

琪琪热码在线中文字幕|

老熟妇色XXXX老妇多毛|

六九姿图片真人|

苍井空电影|

妈妈的朋友5观完整有限中字木瓜|

韩国电影免费观看高清完整版在线熊出没

|

欧也妮葛朗台|

野花视频在线观看最新片|

一起飞在线观看|

丰满人妻一区二区三区视频53|

巨人日本语轮?11姑娘|

狠狠躁久久躁欧美成人AV|

51今日大瓜每日大赛往期内容张|

3Dmax亚洲NINEBOXmod|

母亲3免费完整高清在线观看|

桃子视频在线观看WWW|

av成人电影|

两个人的小森林在线观看|

凹凸国产熟女精品视频|

久久电影网午夜鲁丝片|

欧美影院少妇30匹|

年轻的护士电影完整版|

小舞的淫辱日记(h)小说|

www.55juju.gov.cn|

基zz日本在线观看|

色狗电影网|

大片电影在线观看|

扌臿辶畐的兄妹|

国产精品成人无码久免费|

暖暖在线观看 中文|

深夜福利|

无码粉嫩小泬无套在线观看软件|

年轻人电影www|

国产精品毛片完整版视频|

不收费半夜年轻人看B站软件|

麻豆人妻国产蜜桃蜜臀|

色爽高清大片免费观看|

婷婷色五月|

99精品AV无码波多A片|

翁和媳小莹浴室欢爱52章|

樱花草在线观看播放高清免费|

十七岁高清在线播放免费|

国产又粗又爽又猛的视频A片|

麻花豆传媒剧吴梦梦出演的有几部

|

浴室高潮bd正在播放日本|

小雪好湿?好紧?太爽了|

成长在线观看|

麻豆国产精品无码视频|

两个?我一个bj40分钟宝宝|

无人区在线播放免费观看|

少女たちよ观看动漫第三集预告|

久久www99re在线播放|

在线观看免费永久VUE源码|

免费高清电影网|

午夜精品视频在线观看看|

免费观看已满十八岁的电视剧大全|

久久精品国产视频在热|

丝瓜草莓榴莲香蕉芭乐小猪绿巨人

|

澳门一本道高清在线app|

日系韩系亚洲系列|

日在校园 h|

大片免费播放网站片|

免费视频在线观看网站|

亚洲 欧美 另类 中文字幕|

欧美精品久久久久A片色戒|

菠萝蜜在线观看免费观看电视|

狠狠爱 夜夜撸|

乡村寡妇婬乱A毛片视频|

善良的女房东味道2在线观看|

色欲久久久久久综合网精品|

热九九99香蕉精品品|

欧美人与动牲猛交XXXXBBBB|

韩国电影姐姐在线观看免费观看完整版|

人与动物胶配方视频荷尔蒙|

拔萝卜在线视频免费观看|

Xbox Series X vs Xbox Series X

|

樱花草在线高清免费观看|

日本无码少妇成人久久丫|

免费看少妇高潮成人片|

精品成A人无码亚洲成A按摩|

HD老熟女BBW老椒女|

丰满经的继拇是好事还是恶性|

国产人妻系列无码专区97SS|

无人区码一码二码W358CC|

100免费软件下载安装入口|

欧美最漂亮的av女星|

香港三级日本三级韩级|

日日夜夜撸 在线影院|

67194线在线精品观看|

妈妈的朋友2电影中字翻译|

色五月激情手机|

国产成人无码综合亚洲日韩|

无人区电影高清免费|

?好舒服?快?深点公|

国产成人影院一区二区三区|

左耳电影在线观看免费|

西方37大但免费|

亚洲色大成网站WWW在线|

苍井空有哪些电影|

国产精品理论片|

伦理片esscus2012|

成人免费视频|

邪恶全彩之邪恶爱大全|

久久无码人妻一区二区三区午夜|

av av|

国产在线亚洲精品观|

诱惑美臀|

苍井空电影|

中文无字幕一本码专区|

中文中幕无码亚洲电影|

天下第一社区视频welcome|